Day 14 20/2/2014

Laying of cables on the rig-floor is a very tiresome task, mind bogging if you ask me. This reminds me of the grasshopper. Oh and that’s the structure that holds so many cables and it protrudes into the air just like the legs of the grasshopper. From the grass hopper, all the electrical cables are channels through troughs to all those parts of the rig that need them. Some of the parts that require this power include the 3 DC motors, 2 for Drawworks,one for rotary table, and their respective AC blower motors. There is power for the driller’s console and the dog houses, lighting on the mast, the sensors like hook load sensors, current sensors and cameras. So, you can imagine how many cables we are talking about….so many in fact you will just get tired at their site…..but I was encouraged by the electrical technician, they identify them with codes and uses based on how much you understand the whole system….that's hope for me because at the end of the day I could identify where a few went just from the knowledge I had.

For the electric DC motors, I could see looping done between some terminals so things were easier.

Looking at this collection of cables in the troughs you will wonder how we differentiate the cables that go to one motor from those that go to another motor or pump and its very easy once you understand how the whole system works. This is one of the areas you need some combined effort because just being alone, you can track a cable from the beginning to the end, as you will need help lifting up some cables and pulling others.

Day 12 18/2/2014

Cleaning flood lights….they looked like but they are rig lights! This was our first duty this day. I had the open ended spanner m10, Yes, opening up each of these lamps, wiping them with a clean rug and when dry I would close them up. Of course I had to take care not to damage the bulbs and my skin….of course the edges are not as blunt as a matress that you and caress your hand over.

We then joined our efforts with some floor men to reignforce the mast structure below onto its supports stands in preparation for their carrying or transportation to the next site.

What you are looking at below are the hydraulic motors for the BOP and as Eric was working on them, we took time to learn afew tips from him as we helped him install new oil rings as the previous ones had been used. Basically, they are double acting cylinders that have many valves to direct hydraulic fluid into the various BOP rams lke the pipe rams, annular ram and blind rams.

I actually found this challenging, at the end of the day, (while waiting for tea to be brought) I took time to master how these chains were linked together and it was a maze. You can imagine how much power it takes to lift the end part of this substructure and then what would happen if the chains are not well laid on the pulleys…

Day 11 17/2/2014: Compressor systems

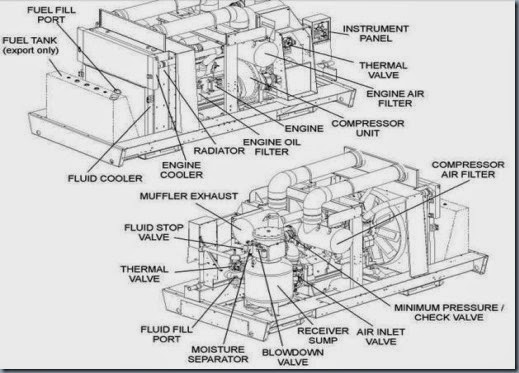

The rig site normally has 5 primary compressor mainly of the Atlas Copco XRHS 1096 type or the Sullair 1150XH series or a combination of the two types. I have worked with both types, Sullair 1150XH at Rig 2 and the Atlas Copco XRHS 1096 at Rigs 4 and 1.

They are a very important part of the system especially when it comes to air drilling operations. During this day, we did most of the work and spent most of the day learning about compressors as we really had to understand how they work if we had to take part in their troubleshooting and maintenance.

The Sullair 1150XH

This is among the compressors Sullair categorises as open frame air compressors with superior performance and reliability with minimal performance. The compressor is equipped with a Sullair rotary screw compressor unit. Compared to other compressors, the Sullair is unique in mechanical reliability and compressor durability. No inspection is required of the working parts within the compressor unit.

The package includes a compressor unit, diesel engine, compressor inlet system, compressor cooling and lubrication system, compressor discharge system, capacity control system, instrument panel and electrical system. The Sullair compressor unit is driven by an industrial engine designed to provide enough horsepower for more than adequate reserve at rated conditions.

The engine cooling system is comprised of a radiator, high capacity fan and thermostats. The

high capacity fan draws air through the radiator, keeping the engine at the proper operating temperature.

The same fan also cools the fluid in the compressor cooling and lubrication system. Prior to passing

through the radiator, the fan air also passes through the compressor fluid cooler (which is mounted adjacent to the radiator). As air passes through the cooler, the heat of compression is removed from the

fluid. The same fan also cools the engines intake air supply. Prior to passing through the radiator and oil

cooler, the fan air passes through an air to air aftercooler. As air passes through the air to air aftercooler

heat is removed which was introduced by the engine's turbo charger. The engine is coupled to

the compressor unit with a non-lubricated vulcanized rubber disc and drive flange-type coupling.

On open frame compressors supplied without fuel tanks, like the GDC ones, they are directly connected to the fuel container from which they continuously suck fuel.

SULLAIR COMPRESSOR UNIT

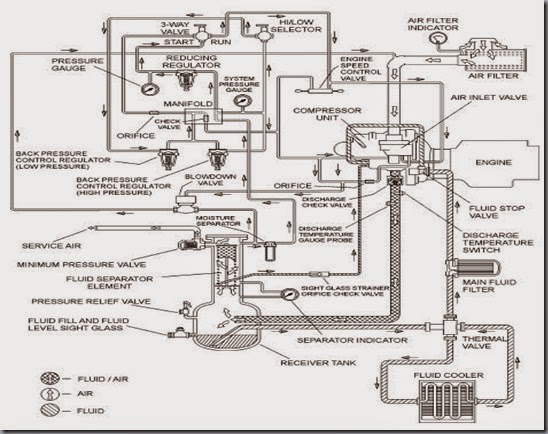

The Sullair compressor unit is a two-stage, positive displacement, flood lubricated-type compressor that provides continuous compression. Fluid is injected into the compressor unit and mixes directly with the air as the rotors turn, compressing the air. The fluid flow has three basic functions:

1. As coolant, it controls the rise of air temperature normally associated with the heat of compression.

2. Seals the leakage paths between the rotors and the stator and also between the rotors themselves.

3. Acts as a lubricating film between the rotors allowing one rotor to directly drive the other, which is an idler.

After the air/fluid mixture is discharged from the compressor unit, the fluid is separated from the air.

At this time, the air flows to the service line and the fluid is cooled in preparation for re-injection.

COMPRESSOR COOLING AND LUBRICATION SYSTEM

The compressor cooling and lubrication system is designed to provide adequate lubrication as well as maintain the proper operating temperature of the compressor. In addition to the cooler and fan, the system consists of a main filter, fluid stop valve and thermal valve. Fluid is used in the system as a coolant and a lubricant. The fluid is housed in the receiver/sump which from this time on will be referred to as the sump. Upon start-up, the temperature of the fluid is cool and routing to the fluid cooler is not necessary. The fluid, taking the path of least resistance, flows to the thermal valve. The thermal valve has two entrance ports and two exit ports. The entrance ports will be referred to as Port A and Port B. Port A accepts fluid from the sump and Port B accepts fluid from the cooler. The exit ports will be referred to as Port C and Port D. Port C routes fluid to the cooler and Port D routes fluid to the compressor. As previously stated, upon start-up, the fluid temperature is cool, and routing to the cooler is not required. The fluid first enters the thermal valve through Port A and then flows on to the compressor

unit through Port D, bypassing the cooler. As the compressor continues to operate, the temperature of the fluid rises and the thermal valve element begins to shift. This forces a portion of the fluid to the fluid cooler through Port C. The cooler is a radiator-type that works in conjunction with the engine fan. The fan draws air through the cooler removing the heat of compression from the fluid. From the cooler, the fluid is routed back to the thermal valve, entering at Port B. Before the temperature of the fluid becomes high enough that Port A is completely shifted, cooled fluid entering at Port B is mixed with warmer fluid entering at Port A. When the temperature of the fluid entering at Port A reaches 210°F (99°C), the thermal element shifts completely causing all fluid to flow to the cooler. The thermal valve incorporates a pressure relief valve, which allows fluid to bypass the cooler, if the cooler becomes plugged or frozen. This helps assure that

fluid will continue to be provided to the compressor for lubrication. After the fluid passes through the

thermal valve it is then directed through the main fluid filter. There the fluid is filtered in preparation for

injection into the compression chamber and bearings of the compressor unit. The filter has a replaceable

element and a built-in bypass valve which allows the fluid to flow even when the filter element becomes plugged and requires changing or when the viscosity of the fluid is too high for adequate flow. After the fluid is properly filtered, it then flows on to the compressor unit where it lubricates, seals and cools the compression chamber as well as lubricates the bearings and gears. The fluid stop valve functions on shutdown when it shuts off the fluid supply to the compressor unit. The fluid stop valve is held open by a pressure signal from the compressor discharge. At shutdown, the pressure signal is lost and the fluid stop valve closes, isolating the compressor unit form the cooling system.

COMPRESSOR DISCHARGE SYSTEM

The Sullair compressor unit discharges compressed air/fluid mixture into the sump.

The sump has three functions:

1. It acts as a primary fluid separator.

2. Serves as the compressor fluid sump.

3. Houses the air/fluid separator.

The compressed air/fluid mixture enters the sump and is directed against the side wall. By change of

direction and reduction of velocity, large droplets of fluid separate and fall to the bottom of the sump.

The fractional percentage of fluid remaining in the compressed air collects on the surface of the final

separator element as the compressed air flows through the separator. As more and more fluid collects

on the element's surface, the fluid descends to the bottom of the separator. A return line (or scavenge

tube) leads from the bottom of the separator element to the inlet region of the compressor unit.

Fluid collecting on the bottom of the separator element is returned to the compressor by the pressure

difference between the area surrounding the separator element and the compressor inlet. An orifice

(protected by a strainer) is included in this return line to help assure proper flow. The sump is ASME code rated at 400 psig (27.6 bar) working pressure. A minimum pressure/check valve, located downstream from the separator, helps assure a minimum receiver pressure of 140 psig (9.6 bar) during all conditions. This pressure is necessary for proper air/fluid separation and proper fluid circulation. A minimum pressure/check valve at the outlet of the receiver is installed to prevent compressed air in the service line from bleeding back into the receiver on shutdown when the compressor is being run in parallel with other compressors tied to a large air system. A pressure relief valve (located on the wet side of the separator) is set to open if the sump pressure exceeds 400 psig ( 27.6 bar). A temperature switch will shut down the compressor if the discharge temperature reaches 265°F (129°C) or 250°F (121°C) for the interstage.

The compressor unit discharges compressed air/fluid mixture through a discharge check valve into the sump. The discharge valve is located on the rear of the compressor unit at the end opposite the drive shaft. The discharge check valve prevents discharged air from returning to the compression chamber after shutdown. Fluid is added to the sump via a capped fluid filler. A fluid level gauge glass enables the operator to visually monitor the sump fluid level.

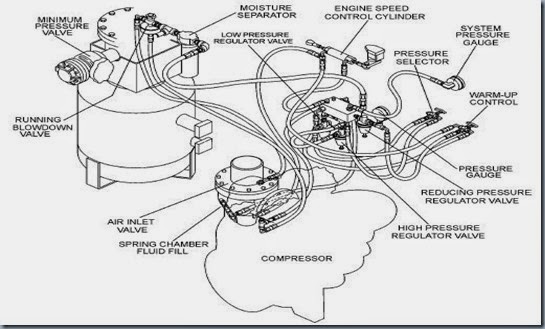

THE CAPACITY CONTROL SYSTEM

The purpose of the control system is to regulate the amount of air intake in accordance with the amount of compressed air demand. The control system consist of an inlet valve, the high and low pressure regulators, the pressure reducing regulator, the blowdown/running blowdown valve, the engine

speed control cylinder, a start-run selector valve, and the high-low selector valve.

START MODE - 0 TO 200 PSIG (0 TO 13.8 BAR)

When starting the compressor, the start-run valve should be in the start position with the high-low selector valve in low position. In the START position, the inlet valve is held closed by the springs in the inlet valve. The valve is cracked open by vacuum in the compressor and is allowed to build up to 200 psig. The reason for keeping the valve closed during start is to allow the engine to warm up without being loaded by the compressor. Air pressure is contained in the receiver tank by the minimum pressure valve which has a set point of 200 psig. (13.8 bar), At this point the valve opens allowing the air to pass to the service valve. After engine has warmed up the run-start selector valve can be switched to the run position.

LOW PRESSURE MODE - 200 PSIG (13.8 BAR)

With the high-low valve in the low position, the startrun valve can now be switched to the run position.

With the service valve open, pressure from the 60 psig (4.1 bar) reducing regulator opens up the inlet

valve and increases the engine speed to full load (1800 rpm). As the demand for air decreases the

speed cylinder retracts, the engine rpm returns to idle (1400 rpm) and the inlet valve closes, where it

stabilizes until the air demand is required.

HIGH PRESSURE MODE - 350 PSIG (24.1 BAR)

When the selector valve is switched to the high pressure position the low pressure regulator is blocked off allowing the high pressure regulator to take over control of the machine. The 60 psi (4.1 bar) reducing regulator fully opens the inlet valve and strokes the speed cylinder for maximum rpm. As the pressure reaches the set point of the system the high pressure regulator cracks open and closes the inlet valve and allows the speed cylinder to return the engine back to idle, until the demand for air is seen.

SHUTDOWN

The blowdown valve is normally closed. When the compressor is shutdown, system pressure backs up to the inlet valve causing the check spring in the inlet valve to close the air inlet valve. This sends a pressure signal to the blowdown valve causing it to open and vent the pressure in the system. After the pressure is vented, the blowdown valve spring returns the blowdown valve to the closed position.

AIR INLET SYSTEM

The compressor inlet system consists of two air filters, a compressor air inlet valve and interconnecting piping to the engine and compressor. Also, nylon tubing from air filter restriction indicator gauges on instrument panel are provided. The air filters are 2-stage units with a safety element dry element-type filter. This filter is capable of cleaning extremely dirty air. However, in such

cases, frequent checks of the air filter will be required. Referring to the instrument panel, the engine air filter restriction gauge or the compressor air filter restriction gauge will indicate when restriction of the air passing through the filter becomes too high. At this time, the air filter element should be changed.

These indicators should be checked daily, after start-up under normal conditions. The compressor air inlet valve controls the amount of air intake of the compressor in response to the air demand.

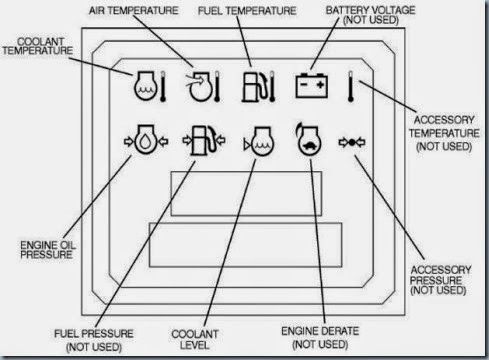

THE INSTRUMENT PANEL GROUP

The instrument panel group consists of an EMS (Engine Monitoring System). On the EMS unit there are ten warning lamps available for system related diagnostics. These diagnostics can be used for system performance monitoring. They are located on the main EMS unit in two rows of five: coolant temperature, intake manifold temperature, fuel temperature, battery voltage, accessory temperature, engine oil pressure, fuel pressure, coolant level, engine derate, and accessory pressure. Beneath the warning lamps is a digital LCD display to scroll through different engine and machine parameters. Digital readouts are as follows:

• The warning lamp is on or flashing when an engine operation problem had been detected by the engine electronics. This usually does not indicate an electronic malfunction.This light can be used along with the EMS lights to determine malfunction.

• Time To Shutdown is defined as the time before the engine will shut down following initial activation of the diagnostic code. It is assumed the engine has been running for at least 30 seconds before diagnostic code activation.

• Start/Restart Time is defined as the time before a shutdown occurs if conditions causing the diagnostic code(s) are present at start up.

• The check engine lamp is used to flash diagnostic fault codes

• The air pressure gauge continually monitors the sump pressure at various load and/or unload conditions.

• The voltmeter monitors the condition of the batteries and the charging circuit. The normal reading is 24 to 28 volts.

• The compressor discharge temperature gauge monitors the temperature of the air/fluid mixture leaving the compressor unit.The normal reading should be approximately 200°F to 230°F (93°C to 110°C).

• The engine switch is used both to energize the compressor's electrical system and engage the engine/starter. The knob-type switch works similar to an automotive key switch; it turns in a clockwise direction with "off" being the first position, "ignition" the second and "start" being the third position. It

also has a built-in anti-restart device that protects the starter from engaging while the engine is running. The switch must be turned back to the "off" position before the engine can be re-started.

• The warm-up control valve is provided for cold weather starting. When placed in the "start" position, the warm-up control valve cuts off the pressure signal to the pressure regulating valve causing the inlet valve to remain closed. It will allow the engine to run unloaded until it is properly warmed up at which time the valve should be set in the "run" position.

• The engine air filter restriction gauge is provided to monitor engine air filter condition. A reading over 20 inches of water or in red zone indicates time to service the air filter.

• The compressor air filter restriction gauge is provided to monitor the unit air filter condition. A reading over 20 inches of water or in red zone indicates time to service the air filter.

• The sump tank separator element restriction gauge is provided to monitor sump tank separator element restriction. A reading over 10 psid (0.7 bar) or in red zone, indicates time to service the element.

• The scroll switch toggled to the left will indicate gauges pertaining to the engine.Toggled to the right will convert reading from Metric to English.

• The compressor discharge high temperature light or the low fuel level light will remain on, indicating the specific problem, until the rotary switch (engine switch) is turned to "OFF" position. When the starter switch is initially turned on, the lights will come on to check bulb function. The lights should go out after 15 seconds.

• The low fuel lamp indicates a low fuel shutdown or open circuit.

• The compressor high temperature lamp indicates a receiver or discharge high temperature shutdown. Could also indicate an open circuit.

• HI/LO selector valve; HI position allows machine to operate at rated pressure (350 psig [24.1 bar]). The LO position forces machine to run at (175 psig [ 12.1 bar]) rated speed.

THE ENGINE CONTROL MODULE

Diagnostic Fault Codes are provided to indicate an electrical or electronic problem has been detected

by the ECM (Engine Control Module). In some cases the engine performance can be affected when the condition causing the code exists. More frequently, however, the operator cannot detect any difference in the engine performance. If the operator indicates a performance problem occurs whenever the Check Engine Lamp is flashing, the diagnostic code may indicate the cause of the problem, and should be corrected. If the operator does not indicate a problem with the engine performance and a diagnostic code is logged by the ECM, it indicates the ECM detected an abnormal condition, but it did not affect performance. If this is the case, unless there are several occurrences of the code in a very short period of time, or, the ECM is indicating an Active Code at the present time, there is most likely nothing wrong with the system. The diagnostic FLASH CODE may be retrieved using this lamp. The lamp is not required for engine operation, however it can be useful to determine Active diagnostic codes. The lamp will illuminate (ON) at initial ECM power-up to test the lamp operation (self test). The lamp will begin to flash (ON, then OFF, ON...) after the five second self test. The sequence of flashes represent the Flash Code diagnostic message. Count the first sequence of flashes to determine the first digit. After a two second pause, count the second sequence of flashes to determine the second digit. Any additional flash code diagnostics will follow (after a pause) and will be displayed in the same manner.

ELECTRICAL SYSTEM

The electrical system is comprised of not only the necessary equipment required to operate the compressor, but also a system to shut it down in the event of a malfunction.

The components of the electrical system are an engine starter (with an integral solenoid), battery, an alternator with a built-in voltage regulator, a compressor discharge temperature switch (which

will shut down the compressor should the compressor temperature exceed 265°F [130°C]), a low coolant shutdown switch and a low fuel shutdown switch. This compressor also incorporates an

engine coolant level detector. This device is located in the top tank on the engine radiator. It will shut the compressor down or prevent it from being started if the engine coolant level drops too low. In addition,

there is a starter protection relay which prevents accidental starter engagement after the engine is running or whenever there is pressure in the receiver/sump. Also, should fuel supply level drop near bottom of the fuel tank, a switch will shut down the machine before the engine actually runs out of fuel.

THE AFTERCOOLER AIR SYSTEM,

The purpose for the aftercooled system is to operate the air compressor in conditions when compressed air temperatures required to be 10°-25°F (5 to 13°C) over ambient temperature.Two discharge valves are provided on all 900XH -1350XH compressor models. One valve is labeled standard air and one valve is

labeled aftercooled air. Closing the standard air (non-aftercooled) valve completely forces the air flow the from receiver tank to the aftercooler. The ambient air, which is drawn through the aftercooler by the engine fan, cools the compressed air as it

passes through the aftercooler core. Cooled air enters the moisture separator where condensation is removed from the cooler air and discharged. This condensate does carry some oil and it should be disposed of properly in accordance with local regulations. From the moisture separator the compressed

air goes to the compressor service valve.

GENERAL

While Sullair has built into this compressor a comprehensive array of controls and indicators to assure you that it is operating properly, you will want to recognize and interpret the reading which will call for service or indicate the beginning of a malfunction. Before starting your Sullair compressor, read this section thoroughly and familiarize yourself with the controls and indicators - their purpose, location and use.

Continued on page 30

PURPOSE OF CONTROLS

| CONTROL OR INDICATOR | PURPOSE |

| ENGINE SWITCH | The engine switch is used to both energize the compressor’s electrical system and engage the engine/starter. The rotary type switch works similar to an automotive key switch; it turns in a clockwise direction with “off” being the first position, “ignition” the second and “start” being the third position. It also has a built-in anti-restart device that protects the starter fromengaging while the engine is running. The switch must be turned back to the “off” position before the engine can be re-started. When re-starting the compressor,make sure receiver tank pressure has blown down to (10 psig 0.7 bar) or less. More than 0.7 bar (10 psig ) can put extra load on the starter.

|

| VOLTMETER | Monitors the condition of the batteries and the charging circuit. The normal reading is 24 to 28 volts. |

| AIR PRESSURE GAUGE | Continually monitors the pressure inside the receiver tank at various load and unload conditions. |

| ENGINE WATER TEMPERATURE GAUGE | Monitors the temperature of the engine water. The normal operating temperature should read approximately 160°F to 210°F (71°C to 99°C ). |

| EMS (ENGINE MONITORING SYSTEM) | Depicts system-related diagnostics. Can be used for system performance monitoring. |

| COMPRESSOR DISCHARGE TEMPERATURE GAUGE

| Monitors the temperature of the air/fluid mixture leaving the compressor unit. The normal reading should be approximately 200°F to 230°F (93°C to 110°C). |

| SYSTEM PRESSURE SWITCH | Prevents starter engagement when the air system is pressurized.

|

| FLUID LEVEL SIGHT GLASS | Monitors the fluid level in the sump. Proper level is always visible in the sight glass. Check the level when the compressoris shut down. |

| COMPRESSOR DISCHARGE TEMPERATURE | Opens the electrical circuit to shut down the compressor when the discharge temperature reaches 265°F (124°C) or 250°F (121°C) for interstage. |

| REDUCING REGULATOR VALVE | Provides regulated air pressure to the inlet valve and engine speed control to open the inlet valve and move engine governor to full speed with warm-up valve in the“run” position. |

| BACK PRESSURE REGULATING VALVE | Provides an air signal to the inlet valve and engine speed cylinder to close the inlet valve and reduce engine speed to control air delivery according to demand. |

| MINIMUM PRESSURE / CHECK VALVE | Maintains a minimum of 200 psig (13.8 bar) in the compressor sump. This valve restricts receiver air discharge from receiver/sump when pressure falls to 200 psig (13.8 bar). Also prevents back flow into the sump during unload conditions and after shutdown. |

| HI/LO SELECTOR VALVE | Select high pressure (350 psig) or low pressure (200 psig) at instrument panel to correspond to operator’s needs. |

| PRESSURE RELIEF VALVE | Opens sump pressure to the atmosphere should pressure inside the sump exceed 400 psig (27.6 bar). |

| AIR INLET VALVE | Regulates the amount of air allowed to enter the air inlet valve. This regulation is determined by the amount of air being used at the service line. |

| BLOWDOWN VALVE | Vents sump pressure to the atmosphere at shutdown. Vents surplus sump pressure to the atmosphere during operation. |

| THERMAL VALVE | Regulates flow of fluid to and around the fluid cooler. Designed to maintain a minimum operating temperature; used for fast warm-up at start-up and to eliminate condensation during operation. |

| START/RUN CONTROL VALVE | Allows the engine to run at unload speed (lower pressure) until properly warmed up |

INITIAL START-UP PROCEDURE OF THE SULLAIR 1150XH SERIES COMPRESSOR AT GDC

The following procedure should be used to make the initial start-up of the compressor:

1. During preparation of a well pad, the infrastructure guys make sure the site is level because of such equipment. It must be made sure that the compressor is positioned on a level surface so that proper amounts of liquid can be added if necessary.

2. Check level of coolant and if needed, add a water and ethylene glycol solution to the engine radiator. Engine cooling system capacity is 30 gallons (113 liters).

3. Fill compressor fluid sump with fluid as recommended. System capacity is 58 gallons (220 liters).

4. Check engine oil level and add if necessary.

5. Check the fuel supply.

6. Check battery electrolyte level and fill if necessary.

7. Close and latch all doors except instrument panel door.

8. Close all service valves and turn arrow on startrun valve handle down to “start” position.

9. Turn engine switch to the “ignition” position.

10. Turn engine switch to “start” position and hold until engine starts (maximum 15 seconds).

11. When engine coolant temperature reaches 110°F (43°C), turn arrow on start-run valve handle to “RUN” position. Compressor is now ready for full load operation.

12. After the initial run, shut the compressor down and refill the radiator and compressor fluid sump as required. Tighten any loose fittings and check fan belt tension.

SUBSEQUENT START-UP PROCEDURE OF THE SULLAIR 1150XH SERIES COMPRESSOR AT GEOTHERMAL DEVELOPMENT COMPANY

On subsequent starts, follow the procedure explained below:

1. Check coolant level and add as needed.

2. Close and latch all doors except instrument panel door.

3. Close all service valves and turn arrow on startrun valve handle down to “start” position.

4. Turn engine switch to the “ignition” position.

5. Turn engine switch to “start” position and hold until engine starts (maximum 15 seconds).

6. When engine coolant temperature reaches 110°F (43°C), turn arrow on start-run valve handle

upward to “RUN” position.

7. Compressor is now ready for full load operation.

4.5 SHUTDOWN PROCEDURE

To shut the compressor down, close the service valves and turn the start/run control valve to the “start” position. Run compressor for approximately 5 minutes; then turn the “on/off” switch to the “off” position. In case of emergency where immediate shutdown is required, this procedure is not necessary. The “on/off” switch should be put in the “off” position immediately.

GENERAL

A good maintenance program is the key to long compressor life. At Geothermal Development Company, there is a good maintenance program that is adhered to, and should keep the compressors in top operating condition. Prior to performing maintenance, the compressor is stopped to relieve all internal pressure.

DAILY OPERATION MAINTENANCE

Prior to starting the compressor, it is necessary to check the fluid level in the sump. Should the level

be low, simply add the necessary amount. If the addition of fluid becomes too frequent, a simple problem has developed which is causing this excessive loss. This should be investigated to find a probable cause and remedy. Also check the engine oil level and the radiator coolant level prior to starting. After a routine start has been made, observe the instrument panel gauges and be sure they monitor the correct readings for their particular phase of operation. After the compressor has warmed up, it is recommended that a general check on the overall compressor and instrument panel be made to assure that the compressor is running properly. Also check the air filter restriction gauges. Should they indicate restriction, replace the elements immediately.

MAINTENANCE AFTER INITIAL 50 HOURS OF OPERATION

At GDC, maintenance is done very often to keep the equipment in top notch performance.

After the initial 50 hours of operation, a few simple maintenance routines can rid the system of any

possible foreign materials, if any. Perform the following maintenance operations to prevent unnecessary

problems.

1. Clean the return line orifice and strainer.

2. Change compressor fluid filter.

3. Check Engine Operator's Manual for any required service.

MAINTENANCE EVERY 100 HOURS

After 100 hours of operation, it will be necessary to perform a check the battery level and fill with water if necessary.

MAINTENANCE EVERY 250 HOURS

Perform the following after every 250 hours of operation:

1. Check fan belt tension.

2. Clean the radiator and cooler exterior. Depending on how contaminated the atmosphere may be,

more frequent cooler and radiator cleaning may be necessary. To clean between fluid cooler and

radiator, the three (3) bolts securing the top of the fluid cooler to the top mounting bracket should be removed, allowing the fluid cooler to swing down on its lower hinge. This will allow easier access to clean between the fluid cooler and radiator cores.

3. Check Engine Operator's Manual for required service.

4. Change the engine oil and oil filter. This is best done when the engine is hot.

MAINTENANCE EVERY 300 HOURS/500 HOURS

This is a time to check and change the compressor fluid, then replace the fluid filter element

PARTS REPLACEMENT AND ADJUSTMENT PROCEDURES

COMPRESSOR FLUID CHANGE PROCEDURE

It is very important to note the correct fluid for the compressors. At GDC, the fluid used is Azolla ZS-46.

Warm-up the compressor for 5 to 10 minutes to warm the fluid. Shut the compressor off and relieve all internal pressure before proceeding. Drain the fluid sump by removing the plug at the bottom of the sump tank. Change the compressor fluid and replace the fluid filter element. For element replacement see procedure for servicing the fluid filter in this section. Fill the sump with fluid according to specifications.

SERVICING THE MAIN FLUID FILTER

The main fluid filter is located schematically in the coolant line between the receiver/sump and the compressor unit. The main filter element is replaceable. For installation of the filter element and o-ring kit. Follow the procedure explained below.

1. The compressor MUST be shut off and system pressure MUST be relieved.

2. Drain by removing drain plug at bottom of bowl and catching drainage in a container.

3. Rotate bowl counterclockwise and remove.

4. Remove element and o-ring from housing and discard. This element is NOT cleanable.

5. Make sure mounting surface of filter head is clean.

6. Apply a light film of fluid to o-ring and place it in its proper position.

7. Place new, clean element in housing, centering it on location in the head.

8. Inspect bowl seal and replace if necessary.

9. Replace bowl. Rotate clockwise and hand-tighten.

10. Replace drain plug. Torque to 15-20 ft.-lbs. (20-27 Nm).

AIR FILTER MAINTENANCE

Air filter maintenance should be performed when indicated on instrument panel by the engine air filter restriction gauge. The air filters are both equipped with a primary element and secondary element each.

The secondary element must be replaced after every third primary element change. DO NOT reconnect the secondary element once it is removed.

ELEMENT REMOVAL

1. Clean the exterior of the air filter housing.

2. Remove the cover/element assembly by loosening the wingnut securing the cover/element assembly.

3. Remove the cover/element assembly from the housing by unscrewing the wingnut.

4. Clean the interior of the housing by using a damp cloth. DO NOT blow out dirt with compressed air as this may introduce dust downstream of the filter.

5. When it becomes necessary to remove the secondary element, pull the element out of the housing.

6. Install the new secondary element over the rod.

7. With the secondary element in place, replace the primary element.

ELEMENT INSPECTION

1. Place a bright light inside the element to inspect for damage or leak holes. Concentrated light will shine through the element and disclose any holes.

2. Inspect all gaskets and gasket contact surfaces of the housing. Should faulty gaskets be evident, correct the condition immediately.

3. If the clean element is to be stored for later use, it must be stored in a clean container.

4. After the element has been installed, inspect and tighten all air inlet connections prior to resuming

operation.

PRIMARY ELEMENT REPLACEMENT

1. Place the element in position over the threaded rod and tighten the wingnut.

2. Install the cover, replace the clamp and tighten the wing screw.

CONTROL SYSTEM ADJUSTMENT

Prior to adjusting the control system, it is necessary to determine the desired operating pressure range as well as the maximum pressure at which the machine is to operate. This pressure must not exceed the maximum operating pressure which is stamped on the machine serial number plate. The following explanation applies to a typical machine with a desired operating range of 200 to 350 psig (13.8 to 24.1 bar). This information will apply to a machine with any other operating range except for the stated operating pressure

1. Start the machine and let it warm-up with warmup valve in "start" position. Check for leaks around connections.

2. Open service valve slightly and turn the warm-up valve to "run" position. Slowly close the service valve, watching the pressure gauge to insure the unload pressure does not exceed 350 psig (24.1 bar) . If it does, the control regulator set screw must be backed out until the compressor will unload. With service valve closed, check and adjust the pressure at the reducing regulator for a 60 psig (4.1 bar) setting. With service valve still closed, adjust the high pressure back pressure regulator on 350 psig [25.5 bar] machines to maintain a discharge pressure of 350 psig (24.1 bar). Machine speed must be 1400 RPM, check instrument panel. Open the service valve to load the compressor to maintain 350 psig (24.1 bar) discharge pressure. Operating speed should be 1800 RPM on the instrument panel.

3. For 200 psig (13.8 bar) machines turn the pres sure selector valve to "low" position. Close the service valve and set the low pressure back pressure regulator to maintain 210 psig (14.5 bar) discharge pressure. Open the service valve to maintain 200 psig (13.8 bar) and check for1800 RPM full load speed. If lower speed is observed, raise the setting of the low pressure control regulator until rated speed is achieved.

SEPARATOR ELEMENT REPLACEMENT

When the need for a separator element replacement is indicated by the maintenance indicator (usually mounted to the air receiver/ separator tank but can also be remote mounted), use the following procedure for separator replacement.

1. Remove the air receiver/separator tank lid by removing the twelve (12) hex head capscrews.

2. Remove the 3/4"-10 jam nut and sealing hex nut from the 3/4"-10 separator hold down rod.

3. Remove the round separator cover plate from the top of the separator element.

4. Remove the old separator element and discard.

5. Scrape the old gasket material from the tank lid mounting surface and the flanges mounting surface on the tank. Be sure to keep all scrapings from falling back inside of the tank.

6. Before installing the new separator element, make sure to lubricate both sealing o-rings on

the element with a lubricating compound or the oil itself. Then install the new separator element, the cover plate, the new 3/4"-10 sealing hex nut, and the 3/4"-10 jam hex nut. Torque the sealing hex nut to 85 to 90 ft.-lbs. (115 to 122Nm). DO NOT over-tighten, as damage to separator element can result.

7. Next, install the tank flange gasket that is provided. Before installing, lubricate both sides of the gasket (i.e. Silglyde). Reinstall the tank lid. Install the capscrews finger tight, then gradually tighten in a crisscross pattern in 4 to 5 steps. Always tighten the capscrews alternately at opposite sides of the cover. Torque lubricated capscrews to 280ft.-lbs. (380 Nm).

8. Clean or replace fluid return line strainer.

9. Clean the fluid return line orifice installed in the side of the compressor unit air end.

Day 10 14/2/2014

At the bottom of the rig structure, there are normally steel wooden palette laid down there before any other part of the substructure follows. As such, after carrying away all the parts of the substructure, what remains are the wooden palettes that need to be loaded too, because they are the first to be laid upon the cellar on the other new well pad.

Generation disconnection is among the last things to be done because no matter how much of the rig you carry away to the new site, you need some power for water in toilets, lighting, computers and charging phones etc. This implies that the main generators can be carried to the new site but the auxiliary one should remain for the little time remaining till most other things are transferred.

My sharp brain still recollects that there were 6 terminals for CAT 3512B generators- the Throttle, 24VDC for PLC, Tachometer, exciter, Power supply spdr, emergency terminals and 3 terminals for CAT 3406-Compressors 1, 2, 3. We did the disconnection of these generator cabins this afternoon and before we left, all of them had been disconnected, cables placed well in their racks and troughs ready for loading and transportation onto the next site.

Day 8: 12/2/2014

Doing a course that encompasses both Electronics and Mechanical aspects of engineering gets you the key to open up anything. I am not limited. Hence when the Electrical technician called us in for dismantling of electrical connections, we were happy, I and my friend Justus to quickly come on board.

So before we started the job, the technician in charge of electrical systems had to explain to us about the electrical systems before we touched anything. The Drilling rig is powered by 4 large diesel engine sets of type CAT 3512B that output 600V,50Hz AC that is changed to 0-750DC through the SCR cabinets in the adjacent room to drive the drawworks, rotary table and mud pumps…all YZC-800A motors of the series excitation type. The DC motors driving the mud pumps and rotary tables are independently driven in a 1 to 2 model with AC-SCR-DC drive. Each of the motors has a max current of 1600A and max speed of 1500rpm. There is one extra auxiliary CAT 3406 generator that has a battery starting system that produces AC voltage used to support minor rig operations and also power up the two LS-12 Sullair compressors that provide pneumatic power, stored in a tank and maintained 0.8-1.2 bar for starting the four massive generators.

Behind the generator rooms, there are large powerful transformers used to take the 600V generated AC voltage down to 220V for basic lighting, 480V MCC and distribution (MCC is motor Control Center). MCCs control the motors and hence the auxiliary components associated with the drilling process. The drilling equipment like mud pumps, drawworks and the rotary table actually consume most of the power and only a small quantity goes to lighting, powering the maintenance, mess, toilets, geology and operations cabins. Each rig at Geothermal Development Company has three triplex type mud pumps, the F1600 type and the maximum power to their motors is limited by the SCR so that the pump can receive more power than what it is supposed to receive.

Rig 1 and Rig 4 have top drive systems though both are spoilt and not functioning. A top drive is just an alternative method of rotating the drill string by putting a motor in the derrick below the travelling block and the hook. This is the only motor that I have ever seen running vertically.

The two LS12 compressors are configured to work together such that one is a master and the other is a slave. In case the master compressor needs more aid to fill up the 2.5 cubic meter tank, it can switch on the slave and can again put it off. The compressor is put on and off manually.

CAT 3512B

The 12 in the model type should be enough to tell you that the engine is a V12 diesel engine equipped with the latest technologies that CAT has showered over its latest models like MEUI (Mechanically Activated Electronically Controlled Unit Injectors). It has an advanced ECM and sensors to control its functioning. Normally, the ECM has a flash file that contains operating maps which define characteristics of the engine like Horse Power and the Torque curves.

The ECM detects the timing and amount of fuel delivered to the cylinders based on the actual conditions and/or the desired conditions at any given time. It also compares the desired engine speed and the actual speed given by the engine speed sensor. Desired engine speed is determined by the throttle signal and other inputs and if the desired engine speed is higher than the actual one, the ECM injects more fuel to increase actual engine speed.

Thus the ECM controls fuel injection by varying the signals being sent to the injectors. We know that the injector only pumps fuel when its solenoid is energized by a high voltage signal, so by controlling the timing and duration of the high voltage signal, engine timing and RPM can be controlled. The limits of the fuel injection are on the flash file in the ECM. ECM normally determines the timing by calculating the TDC of each cylinder and decides when each of these cylinders should fire. The ECM configurations can be done by connecting an adaptor cable to the ECM and computer running CAT SIS or a lighter CAT ET. I remember using CAT SIS 2012B and playing around with a few flash files in the “Test ECM mode”.

Otherwise, for any of us who has been in the automotive industry, apart from the pneumatic starting, the engine is just the same-with alternator, fuel filters (these are larger), fuel priming pump, engine oil pump, turbocharger, inlet air manifold, fuel transfer pump, exhaust manifold, air control valve, Clean Gas Induction (CGI) actuator, oil cooler, oil filters etc….just like any large Diesel engine.

Day 9: 13/2/2014

Rig down is the process of disassembling all connected components of the drilling rig, and putting them apart for transportation to another demarcated patch for the next well. It is the duty of the infrastructure team at GDC to prepare patches called drilling pads or well pads for the drilling team to start working on. There is always a drilling plan followed by the drilling team led by the drilling supervisor and the tool-pusher to ensure that logistics of drilling set-up and rig transfer are made in the correct manner.

During this day, after participating in the safety meeting, the agenda was lowering the substructure and mast. Both tasks are done with respect to check lists to ensure nothing goes wrong during the procedure. None of us believed the substructure could be lowered from where it was held, high soaring above us to a lower level till we attended the procedural meeting where the checklist was read and confirmed as we took our positions to alert the required personnel incase we saw anything unusual.

As an intern, GDC does not give you an opportunity to recommend much but I would recommend that there should be a clear means of communication between any personnel on the ground and those on the rig floor in case someone has anything to report because of an incident I witnessed at Rig 2 where the hydraulic ram that is used to lower the substructure subjected huge pounds of force on some part of the structure and went through it. We could scream as loud but the floor personnel operating the YHCX derrick and substructure buffer control box could not hear due to the noise, till the damage was done and yet we saw it all! This is very bad, not because we couldn’t help but because there are no channels of communication. Why not have some linked microphones and headphones during such billion shilling operations that put the rig at risk? I just hope someone is reading this….

Anyway, the substructure is lowered by two persons, the driller in the driller’s cabin and the personnel operating the derrick and substructure buffer control box that remotely controls the hydraulic ram during this operation.

I remember perusing some items in the ZJ70/4500D 2010-106 Mast inspection Checklist and I was impressed. It is just a list to ensure that everything is in its secure position to ensure there is no damage to the very expensive equipment.

Having done that, I spend the rest of the day inspecting drawworks chains and fixing some safety pins that had come out. Some of the endplates had also been pushed out of place during running of the 2 drawworks DC motors.

How old is this technology? I don’t know, but using the 8 pen Drilling recorder to log drilling/well data on very huge graph papers? Wow, I did not see any of these drilling recorders at work and I would understand that pretty well. I’d rather use the data logged in by the computers.